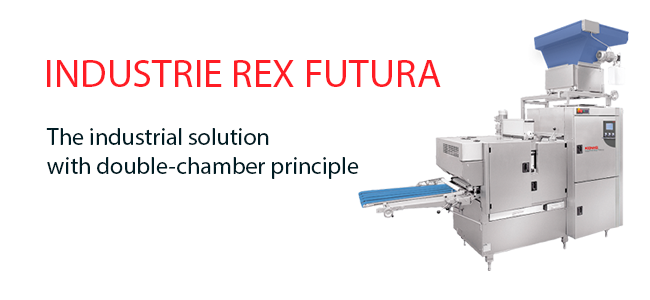

The industrial solution with double-chamber principle

Two drum ledges of different sizes, making for two different chamber sizes, characterise the Futura version. This principle makes it possible to extend the range of processing weights of the dough pieces enormously. Switching between the chamber types is performed electro-mechanically by pressing a button without any interruption of the production sequence. Therefore it is possible with the Industrie Rex Futura to choose from two different, combinable weight ranges.

- automatic dough dividing and rounding machine according to the Rex principle

- different chamber sizes with enlarged dividing drum

- max. hourly capacity of approx. 14,400 pieces with 40 strokes/min in the 6-row version

- simple dough supply via roller hopper with safety light-grid

- machine weight: approx. 1500kg

- power supply: 6 kW

- industrial PLC control

- stainless steel design

Weight range Number of rows Max. hourly capacity

30-100G 5 12000 combinable

weight ranges

95-200G 3 7200

30-100G 6 14400 combinable

weight ranges

40-140G 3 7200

The dough is filled into the roller hopper (via a pre-portioning hopper).

Rotating star rollers (dough feeding stars) cut the dough into suitable portions (depending on the single weight of the dough pieces) which are then conveyed into the dividing area.

The horizontally moving slider presses the dough into the opening of the dividing drum. The excess dough is removed by a scraper ledge and returned to the dividing area.

After an anti-clockwise rotation by 180°, the dough pieces are discharged to the intermediate belt. – This step is particularly important for high processing rates as it allows the dough to rest between portioning and rounding.

The dough pieces are subsequently rounded with an oscillating rounding drum. The size and type of the rounding drum are determined by the dough consistency and weight.

In the bottom-most position, the dough pieces are discharged onto the spreading finger belt.