Description

MAIN FEATURES

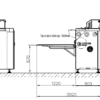

Based on the “Rex” technology that’s gentle on the dough, the Basic Rex divides and rounds dough pieces in 6-, 5- and 4-row versions. The tried-and-tested head machine obtains an hourly capacity of up to 9,000 pieces.

- gentle operation according to the Rex principle

- 6-, 5- and 4-row machine versions

- easy change of row number possible

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- simple operation via handwheels

- simple dough supply via chute hopper with safety light-grid

- optionally available with spreading finger belt or discharge belt

- net weight approx. 800 kg

- power supply: approx. 1.5 kW

- Stainless steel cladding

Weight range Number of rows Piston size Max. hourly capacity

15-40G 3\4\5\6 SK 47 4500/6000/7500/9000

22-55G 3\4\5\6 SK 51 4500/6000/7500/9000

25-65G 3\4\5\6 SK 54 4500/6000/7500/9000

35-85G 3\4\5\6 SK 58 4500/6000/7500/9000

50-110G 3\4\5\6 SK 63 4500/6000/7500/9000

52-115G 3\4\5\6 SK 65 4500/6000/7500/9000

55-125G 3\4\5 SK 67 4500/6000/7500

60-135G 3\4\5 SK 70 4500/6000/7500

The dough is filled into the hopper.

Optimised dough portions (depending on the single weight of the dough pieces) are conveyed into the dividing area by means of rotating star rollers (dough feeding stars).

The horizontally moving slider presses the dough into the opening of the dividing drum. The excess quantity of dough is conveyed back to the dividing area by a scraper ledge.

After an anti-clockwise rotation by 90°, the rounding of the dough pieces is performed by an oscillating rounding plate. Depending on the dough consistence and dough weight, the rounding eccentric can be adjusted.

After another 90° rotation, the dough pieces are transferred to the discharge belt.