The PU Integral automatic industrial baking oven features its independent baking zones for the regulation of temperature, air volume and humidity that enable optimised product quality for all baked goods. To achieve this, Koenig uses for the PU Integral an innovative sealing system for the individual baking zones. This way, the oven works similar to several individual ovens, adjusted to the different baking time. The production of part-baked products with very short baking times is realised with two independently working loading trolleys.

High product variety with best baking results

- individual baking zones ensure ideal baking results for all products for par-baked and ready baked products such as for example: wheat rolls, lye bread rolls, freely set bread, tin loaves, pastry and pizza

- baking pates in various thicknesses available in perforated or solid execution, for rye bread rolls and special bread rolls, also teflon-coated or with a thin stone layer

- up to four independent individual baking zones enable exact regulation and control of temperature, air quantity and humidity during the baking process.

- for an ideal baking process, the following parameters may be set independently for each zone:

- zone humidity – controlled by measuring the actual value

- zone temperature – controlled by measuring the actual value of the zone’s individual heater

- our innovative sealing system for the individual zones is the precondition for the zone independent control and thus ideal baking results

- the use of two independently working loading trolleys can reduce the cycle and baking time considerably

- independent sensory test showed excellent baking properties for par-baked bread rolls

No contradiction: Large baking area – small footprint

- the compact design requires minimum footprint compared to conventional tunnel or deck ovens

Automatic loading system included

- horizontal transport system for loading and unloading the oven

- the products can be fed via a transfer belt or a retracting unit

- the use of two independently working loading trolleys can reduce the baking time considerably

- the automatic depanning unit enables simple product unloading onto subsequent components

- integrated pre- and post-spraying of the products

Hygienic Design

- each unloaded baking plate is cleaned by the integrated brush cleaning system

- easily accessible underneath oven

- extendible catch trays in the loading and unloading area of the oven

- smooth surfaces enable easy cleaning

- wide-opening maintenance doors for easy access to baking chamber

Efficient energy use – Minimum heat loss

- optimum baking area-surface-ratio ensures low heat radiation

- adjustable, targeted energy input into each individual baking zone (heat energy and humidity) reduces the total energy consumption

Maintenance and Service

- thanks to the easy accessibility no special tools required for any maintenance works

- long maintenance intervals guarantee high availability

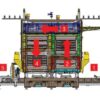

1. A plate carrier stacks the baking plates, which rest on the corners, into tower 1

2. A stacking system with retaining handles transports the baking plates through the separated baking zones

3. The plates are shifted to tower 2 via a sliding system

4. The stacking system transports the plates to the oven discharge

5. Depanning unit with rotating brush

PU2500x1300 PU3000x1300

Plate size (mm) 2500×1300 3000×1300

Number of baking plates(piece.) 26 / 28 / 30 / 32 / 34 / 36 26 / 28 / 30 / 32 / 34 / 36

Active baking surface(sqm) 84sqm / 91sqm / 97sqm / 104sqm / 110sqm / 117sqm 101sqm / 109sqm / 117sqm / 124sqm / 132sqm / 140sqm

Minimum cycle time 1 loading trolley: 25 sec

2 loading trolleys: 19 sec 1 loading trolley: 25 sec

2 loading trolleys: 19 sec

Baking time 1 loading trolley:

11.0 min – 26 baking plates

11.5 min – 28 baking plates

12.5 min – 30 baking plates

2 loading trolleys:

10.0 min – 32 baking plates

11.0 min – 34 baking plates

11,5 min – 36 Backplatten 1 loading trolley:

11.0 min – 26 baking plates

11.5 min – 28 baking plates

12.5 min – 30 baking plates

2 loading trolleya:

10.0 min – 32 baking plates

11.0 min – 34 baking plates

11,5 min – 36 Backplatten

Maximum product height at baking plate height(163 mm / 190mm) 110mm / 140mm 110mm / 140mm

Floor space cyclotherm 8400x4890mm 8400x5390mm

Floor space thermo oil 8400x4590mm 8400x5090mm

System height cyclotherm 4759 – 5411mm 4759 – 5411mm

System height thermo oil 5110 – 5870mm 5110 – 5870mm